Kılavuzlu Dam Automation

For the first time in Turkey, an automation scenario based on seismic movements has been implemented. The success of this project has led to the initiation of new projects for major public investments.

Guided Dam Automation: Seismic Sensitive Intelligent System and Risk Management

The Guided Dam Automation, which was put into practice for the first time in Turkey, has a management system that automatically responds to seismic movements and has taken an important step to increase the safety and efficiency of dams. With this project, pre-determined automation scenarios for dams are activated during natural disasters such as seismic movements and ensure that dams are managed safely. The system works integrated with the Seismologger device that detects seismic warnings and starts all automatic control processes when seismic movement is detected. In this way, the safety of the dam is ensured in sudden situations such as earthquakes. Within the scope of the Guided Main Channel Automation, the artificial intelligence-supported system collects and monitors the data from each measurement station in a single center and adjusts the opening-closing movements of the gates in line with this data. This project not only controls the water levels of dams, but also ensures that effective precautions are taken against natural disasters. With automation sensitive to seismic movements, artificial intelligence-supported systems and emergency scenarios, dams have been made safer. In this way, a model has been created that paves the way for new projects to ensure the security of important public investments in Turkey.

Effective Water Management and Flow Control in Guided Irrigation Fields with SCADA Supported Automation System

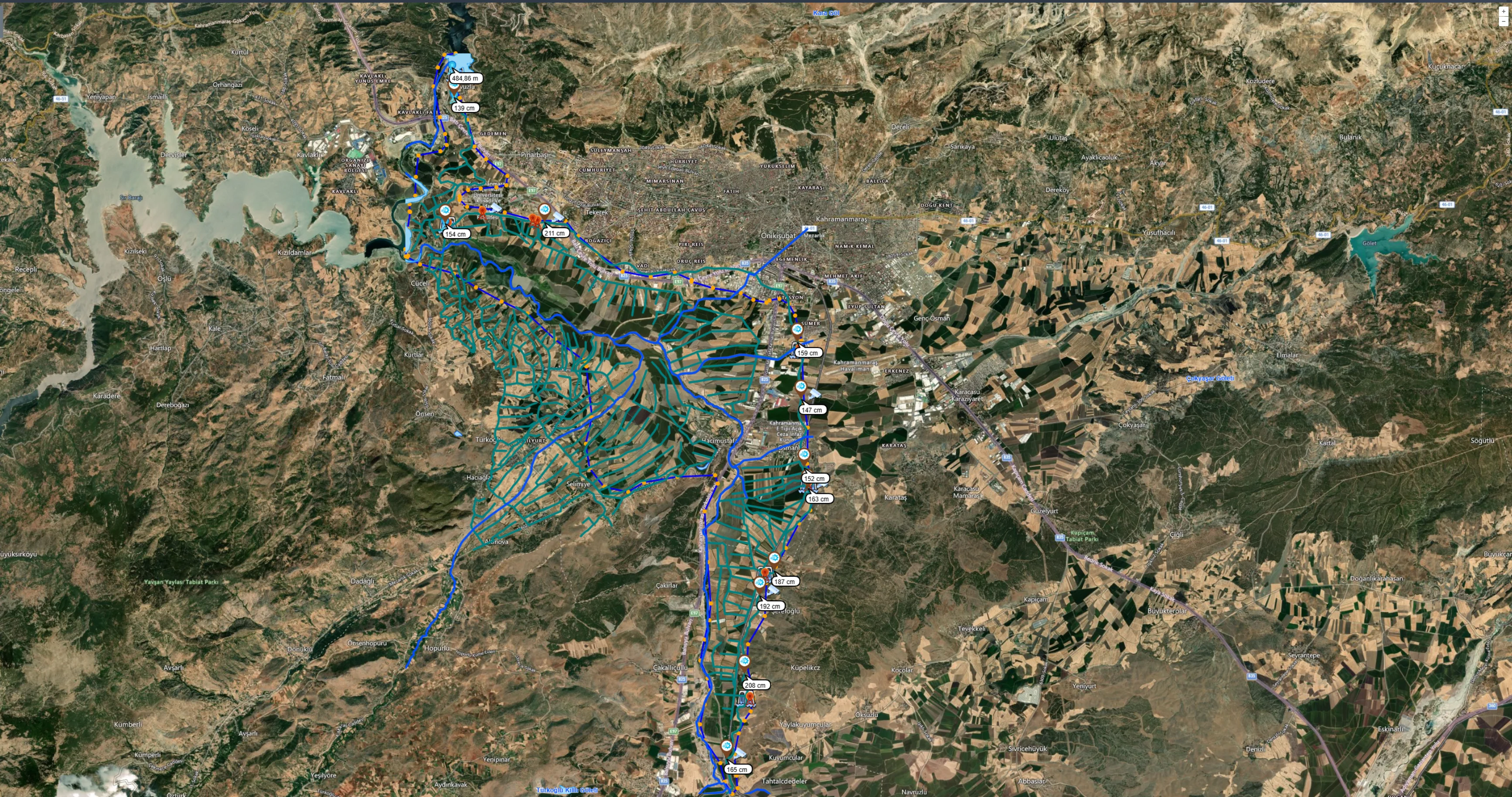

With the automation and scada system established in the DSI 20th Regional Directorate Piloted Irrigation field, the instantaneous water demand can be monitored and revised according to instantaneous changes, and the valve opening rates can be managed remotely or autonomously under the management of the administration in order to guarantee that the necessary water flow rates can be provided on time for the operation of the irrigation plan.

Effective Water Management and Instant Intervention Opportunities with Flow-Based SCADA System

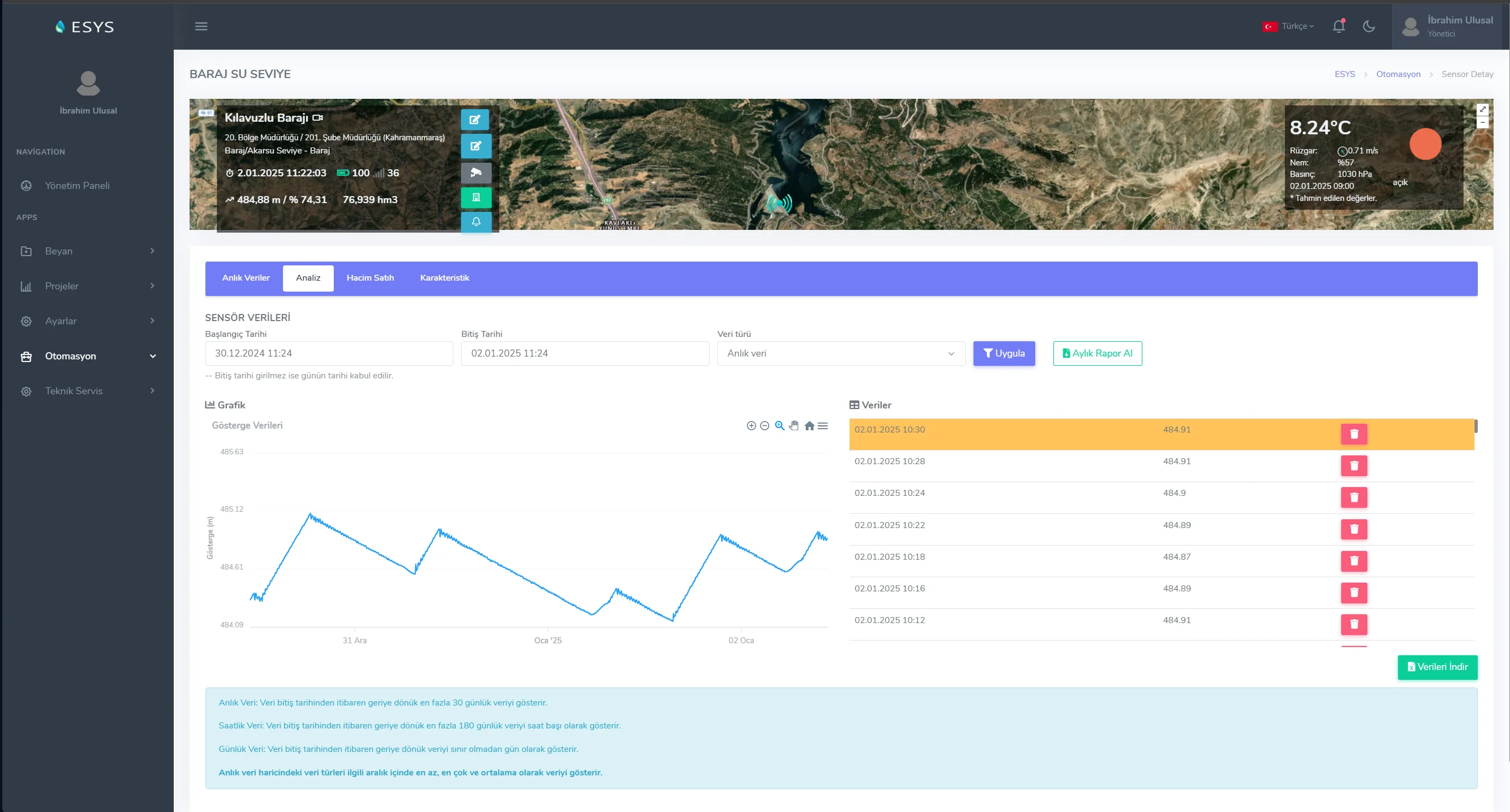

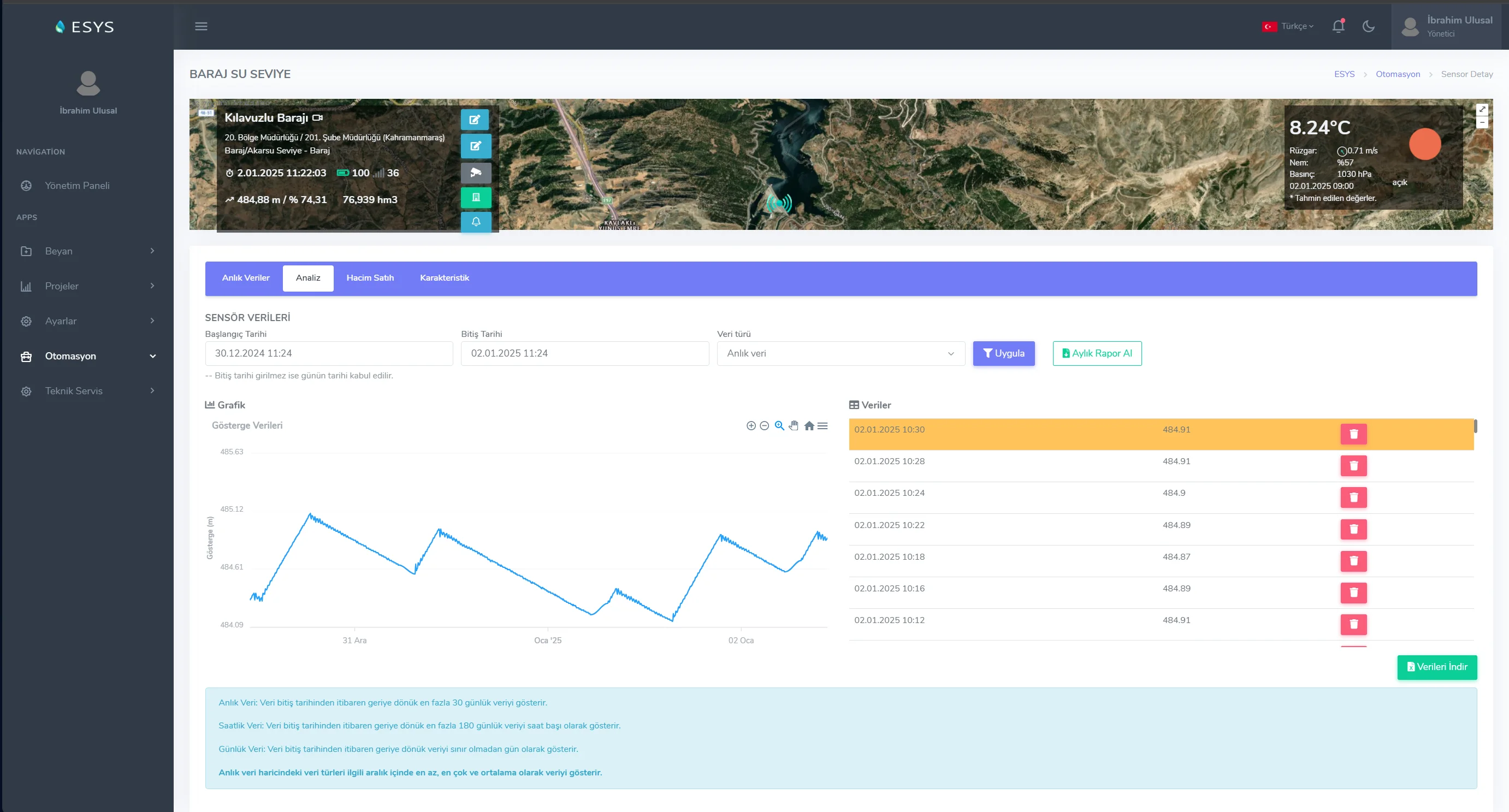

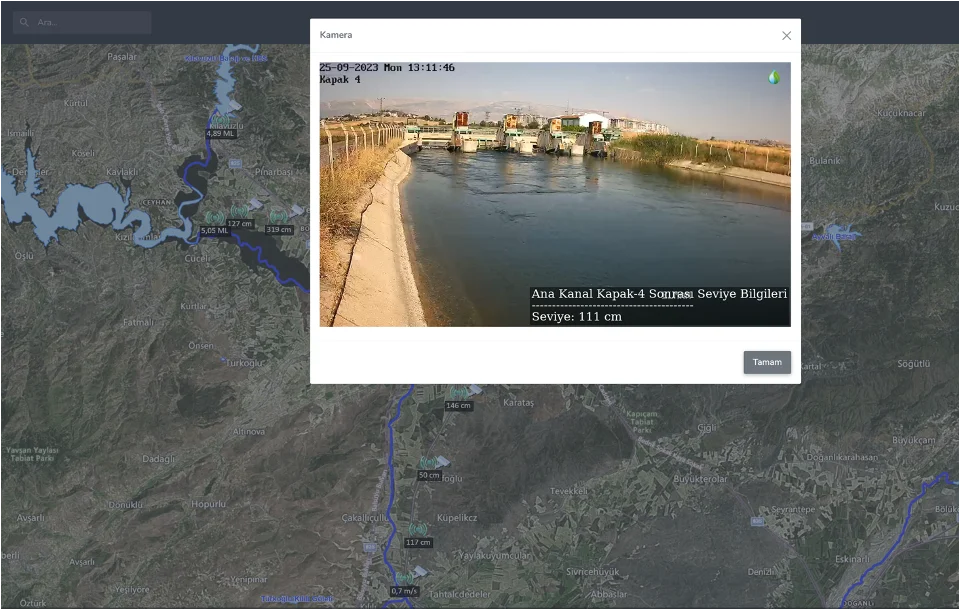

The established flow-based SCADA system ensures timely and safe water supply, while monitoring system safety limits 24/7 to reduce flood risks due to lake levels. The realization rate of water allocation can be observed instantly and interventions can be made when necessary. In case of deformations that may occur in the operation field or channel structure, the system increases operational efficiency by providing instant intervention. Outside of working hours, the hierarchical management console is activated for authorized persons, shortening intervention times in emergency situations. Interventions can be made in line with instant or planned scenarios at each automation point, thus ensuring rapid regulation of the water amount regardless of factors such as weather, distance, transportation cost, intent, and negligence. Alarms can be set for the targeted flow rate due to seasonal variables or other critical factors, thus preventing loss of life and property by sending instant warnings to personnel via mobile devices. While the cover automation provides savings on personnel, vehicles and fuel, with GIS-based digitalized layered water management, water allocations and management are made based on instant data, and water resources can be used effectively. Thanks to artificial intelligence-supported planning, adverse effects that may occur due to seasonal effects, human errors and changing water demands are minimized, and the results of the interventions can be monitored graphically or tabularly. In addition, thanks to the sensors supported by industrial management devices, automatic closing of the covers, emergency notifications and interruption of water transmission can be provided for emergencies such as seismic activities without the need to establish additional stations. In cases where communication is interrupted, the activation of system security protocols ensures the safety of life and property.

Safe Water Management with Autonomous and Remote Control Systems for Guided Irrigation Canals and Dams

In the Klavuzlu Irrigation Canal, autonomous and remote manual control of 27 gates located at 7 points is provided with Artificial Intelligence. In addition, a Live Image Monitoring System has been established at 7 different points for instant visual monitoring of the gate points located in the Klavuzlu Dam and irrigation line. While there are 14 non-contact level measurement stations in the project area for effective control of the Klavuzlu Dam and irrigation line, 7 earthquake sensors have also been commissioned to enable autonomous or remote manual intervention in the event of an earthquake. One of the biggest advantages of the system is that the flow-based gate automation works interactively under the control of the Administration and is managed based on a hierarchical authority principle. In this way, instant changes that occur over time can be quickly adapted by considering the end pattern of the irrigation area. It is aimed to contribute to agricultural production and food safety by targeting water supply security.

Project Implementation Stages

1. Stage Planning and Design

At this stage, the infrastructure of the dams' automatic control systems is designed. Each measurement station continuously monitors the dam's water level, flow rate and other critical data. Considering the risk of seismic movements affecting the dam, seismologger devices are placed and the data of these devices are transmitted to a central control system. The infrastructure where artificial intelligence algorithms will operate is created and the data provided by each station is automatically analyzed and integrated with decision mechanisms. In addition, emergency scenarios necessary for the safety of dams are prepared and the parameters that will trigger these scenarios are determined.

2. Stage Integration and Software Development

In the second stage, artificial intelligence-supported applications come into play. This application analyzes the data provided by each measurement station and ensures the safe management of the dam. Artificial intelligence automatically adjusts the movement of the gates according to the determined flow rate and quickly detects any changing situation. In addition, data from different points of the dam is transferred to a central control panel. Critical warnings and alarm systems are created according to seismic movements, water level changes and other environmental factors. These warnings are monitored by the risk management center and, when necessary, notifications are sent to the authorities at the same time. Thus, in the event of any emergency, the dam management can intervene quickly.

3. Stage Implementation and Monitoring

In the final stage, the dam automation system is activated on site. In the event of detection of seismic movements, emergency scenarios are activated and certain commands are immediately put into action. In the system, critical points are monitored with cameras and visual verification is provided. This visual dominance is strengthened with land support mechanisms, thus increasing the efficiency of the system. In addition, at this stage, the dam's water level, flow rate and other critical data are monitored instantly. Artificial intelligence algorithms analyze all kinds of variable situations and automatically initiate the necessary interventions. During emergencies such as earthquakes or floods, automatic control of the gates helps minimize risks. In this way, dams not only operate efficiently, but are also managed safely during any natural disaster.

Kılavuzlu Dam Automation Products We Use